|

Abell Foundation

For the years 2022-2023, Solar Oysters received grant funding from the Abell Foundation in partnership with Chesapeake Bay Foundation (CBF) to support their oyster gardening program and further develop the SOPS prototype. CBF provided spat-on-shell oysters to SOPS in October 2021, which were grown until November 2022 and produced around 36,100 oysters. That same November, the 2022 batch was outplanted at Fort Carroll in the Baltimore Harbor, on a protected DNR oyster restoration reef, while a new batch for 2023 was onboarded to SOPS. The 2023 batch was very densely set, producing 356,000 oysters, and was outplanted on June 26, 2023, at the same restoration reef near Fort Carroll. As part of this grant, Solar Oysters hosted University of Maryland Baltimore County (UMBC) Interdisciplinary Consortium for Applied Research in the Environment (ICARE) graduate student to design and conduct an experiment using the 2022 oyster cohort. The experiment aimed to evaluate how rotation of oyster cages on SOPS affects oyster growth. The CBF oysters were sampled every 3 weeks from April 2022 to October 2022 for height measurements. Traditional cages were also suspended from the side of SOPS for comparison. Results showed a higher survival rate, 85-90%, in oysters grown on SOPS than in traditional and static cages. CBF and Solar Oysters also facilitated Baltimore City STEM teacher visits to SOPS to discuss the design and biological concepts of the technology. Over the past two years, Solar Oysters was able to increase the numbers of oysters grown for restoration in the Baltimore Harbor by more than 60%. The SOPS technology has been proven to grow healthy, market size oysters, at an 85- 90% survival rate. Although this grant has concluded, Solar Oysters and CBF will continue their partnership to advance oyster restoration and improve bay water quality |

As part of the end of this grant, we interviewed Kellie Fiala of CBF to get her take on the work we have done together. To read the full interview, click here. |

Chesapeake Oyster Innovation Award Program

For year 2023, Solar Oysters received funding from the Chesapeake Oyster Alliance and Chesapeake Bay Trust to design, build, and implement an automatic spray wash bar system to test on a SOPS prototype ladder. Heavy biofouling, an accumulation of algae and microorganisms, can hinder oyster growth by competing for available food sources and weaken aquaculture equipment. Mitigation of biofouling via pressure washing is very labor intensive and can take 5-8 hours on the SOPS prototype. By mounting a spray bar overtop of a ladder system, this process can be reduced to just minutes. The project will run from April to September.

In 2020, funding was awarded to Morgan State University and Solar Oysters to build and evaluate a prototype spray header system to automatically remove biofouling as part of the F3 Tech Accelerator Program. Beneficial spray nozzle type and pressure ratings were identified as a result. Funding from the Chesapeake Oyster Innovation Award Program will bring this design to its final stages of examining flow and intake rates for implementation on current and future SOPS.

For year 2023, Solar Oysters received funding from the Chesapeake Oyster Alliance and Chesapeake Bay Trust to design, build, and implement an automatic spray wash bar system to test on a SOPS prototype ladder. Heavy biofouling, an accumulation of algae and microorganisms, can hinder oyster growth by competing for available food sources and weaken aquaculture equipment. Mitigation of biofouling via pressure washing is very labor intensive and can take 5-8 hours on the SOPS prototype. By mounting a spray bar overtop of a ladder system, this process can be reduced to just minutes. The project will run from April to September.

In 2020, funding was awarded to Morgan State University and Solar Oysters to build and evaluate a prototype spray header system to automatically remove biofouling as part of the F3 Tech Accelerator Program. Beneficial spray nozzle type and pressure ratings were identified as a result. Funding from the Chesapeake Oyster Innovation Award Program will bring this design to its final stages of examining flow and intake rates for implementation on current and future SOPS.

|

The Future of SOPS

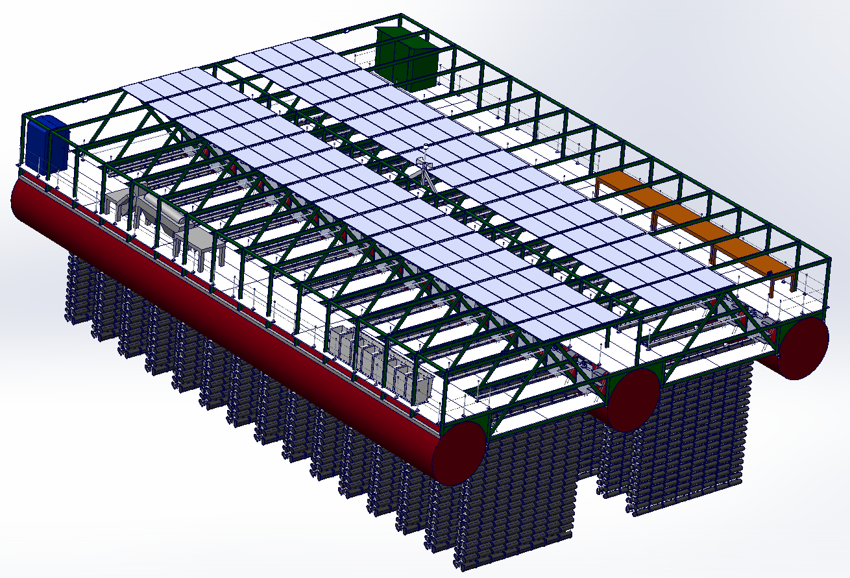

Moving forward, Solar Oysters aims to build and deploy a large SOPS model that can support production of over 2 million oysters per year. This design reaches 90 ft x 60 ft (0.12 acres) and is equipped with 30 rotatable ladders, 120 solar panels, and an 8000+ oyster cage capacity. Solar Oysters has two lease applications pending for water column sites in Cove Point, MD where we hope to deploy several SOPS units and expand our impact! This site will be used as a research and development location for our technology. |